See How Your Jackets Are Made

Creating a jacket is more than just putting fabrics together; it’s an art that blends craftsmanship, innovation, and advanced techniques. Let’s explore how we make your jackets stand out with exceptional quality, style, and functionality.

01.

Pattern Creating

Pattern is used as a blueprint for cutting and sewing the individual pieces of the jacket.

02.

Fabric Cutting

use a CNC cutter to cut fabric into the desired shapes and sizes for garment construction

03.

Jacket Sewing

Assemble the individual pieces of fabrics to create a finished garment by using sewing machine or other equipment.

04.

Finishing

Add the finishing touches like button, zip, patch, pressing etc to the jacket to make it look complete and polished.

05.

Quality Controling

A series of inspections and tests to verify that the jackets are free from defects and meet the required standards

06.

Packaging and Shipping

The inspect passed jackets would be packaged and shipped to the customer in a timely and cost-effective manner.

Wisely Utilize Materials - Save Cost

Fabric is the most costly part of garment manufacturing, accounting for more than 50% of a garment’s total cost. Choosing the right fabric is crucial for producing a high-quality jacket. For instance, a jacket designed for cold weather may be made from a heavy, insulating fabric such as wool or down, while a summer jacket may be made from a lightweight, breathable fabric such as cotton or nylon. Additionally, the quality of the fabric impacts the jacket’s durability and appearance, making it essential to opt for a high-quality fabric that will endure over time. See what set us apart on the utilize of materials.

Stable Fabric Suppliers - Reduce Cost

Decades of strong relationships with fabric suppliers: our valuable asset for cost savings and improved service

- Predictable pricing and cost savings

- Improved quality control

- Well done color continunity

- Consistent availability of latest technical and functional performance of fabric

- Better service and support

Strict Fabrics Test and Relaxation- Avoid Bulk Defects

By testing and relaxing fabrics before production, we can prevent costly defects and ensure customer satisfaction. Proper fabric relaxation of 48-72 hours can avoid shrinkage, wrinkling, and other defects. We arrange fabric's physical and chemical test to meet industry standards and customer requirements.

- Color fastness to washing, water, rubbing etc

- Roller shading checking

- Dimensional stability checking

- Tear strength, Seam slippage, Bursting strength, Abrasion resistance test etc

Brand Accessories - Quality Assurance

See how we set our jackets apart from competitors and create a distinctive and appealing look for their customers

- Quality is guaranteed as buttons, zippers, and snaps are sourced from reputable brands such as YKK, SAB, SBS, and Maxim

- A diverse range of printing methods and embroidery patterns, such as digital prints, screen prints, foil prints, silicone prints, glitter prints, transfer prints, reflective prints, and 3D embroidery to name a few.

- A comprehensive collection of accessories for your selection, including beads, ribbons, tapes, piping, toggles, stoppers, buckles, shrink buttons, zippers, snaps, labels, badges, foam, and others

State-of-the-Art Machines - Efficient, and Less Waste

- High effectively - Automatic spreading machine that layer fabrics on the cutting table

- Minimizing Waste - Pattern experts wisely utilize fabric to Create Pattern Markers.

- Accurately - Automatic cutting machine uses a laser beam to cut through layers of fabric.

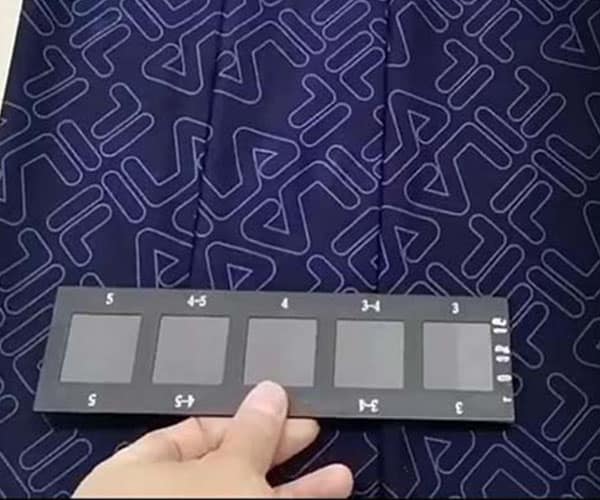

- In order - Operators sort, bundle and number of garment plies

- Correctness - QC inspect cut parts and arrange re-cutting of the defected panels

- Lean manufacture - Workers fuse garment components

Well organized sewing process - lean production

At Moondeng, we provide comprehensive quality assurance services throughout the entire jacket sewing process to safeguard your reputation and brand.

01.

Well trained before bulk production

Before the start of mass production for each order, all workers will undergo training to enhance their understanding of the tasks at each stage and to ensure that they work in accordance with a well-defined process flow. This approach will help to minimize the occurrence of defects.

02.

Experience and expertise

Moondeng has 15 years of experience in jacket sewing, and our workers have specialized skills and knowledge in that area.

03.

Equipment and technology

We have invested in modern, high-quality sewing equipment and technology, like Automated Sewing Machines, Heat Press Machines, Seam Sealing Machines, Laser Cutting Machines, Down Filling Machines etc, which allows us to produce jackets efficiently and accurately.

04.

Attention to detail

We place a strong emphasis on attention to detail in the sewing process, ensuring that each stitch is made precisely and the final product is of the highest quality.

Whole producing line 100% inspection

In-line Inspection

At the start of the assembly line, our quality control team performs a thorough inspection of partially stitched garments, checking for any defects and offering solutions to improve any stitching faults that are found. Only those pieces that pass the inspection and are defect-free are allowed to proceed to the next stage of the manufacturing process

Randomly Inspection

Throughout the entire sewing process, our quality control team conducts random checks of jacket pieces at each workstation every hour to ensure that each worker is producing high-quality jackets. If any defective products are identified during these checks, they are immediately picked out and sent for repair.

End of Line Inspection

After the sewing process is completed, our quality control team conducts a 100% check of fully stitched garments. Any defective pieces or loose/uncut threads are repaired before the garments are sent to the finishing section

Initial Garment Checking

Prior to ironing the garments, our quality control team leads an initial inspection that includes a visual examination of various aspects such as loose and uncut threads, garment construction, labeling, workmanship, stitching defects, fabric defects, as well as measurement checking. Any garments found to be defective are promptly sent to the repair section for correction

Final Garment Checking

After ironing/pressing the garments, our quality control team conducts a recheck of measurements and visual aspects, including the shade variation and the correct labeling of size and content. Any defective garments detected at this stage are immediately sent back for repair

Final Quality Audit

The final audit will be conducted by either our in-house quality control team, the customer’s own quality control team, or a third-party audit party like SGS, HQTS, etc., as the customer nominated. The audit will follow the shipment audit method (AQL 2.5-4.0), with a certain percentage of garments being inspected.

Ironing

Needle detection

Folding and Packing

Preparing of shipping documentation

Well organized post inspection

Efficient organization of the finishing and shipping processes not only saves time but also helps to avoid additional costs

- Ironing (steam press)

Our operators use an ironing treatment to press the finished garments, which removes any creases and wrinkles from the jackets, giving them a fresh and well-formed appearance.

- Folding and Packing

Our packing workers carefully fold each jacket and place them into polybags, which are then manually or automatically placed into cartons. Price tags, hang tags, and any other necessary tags are attached to the garments after folding.

- Needle Detection

As a safety measure, the folded garments pass through a metal detector machine to detect any broken needles or other metal items. This step is mandatory for certain product types, particularly for children’s garments.

- Preparation of Shipping Documents

Our documentation department prepares the packing list, invoice, certificate of origin (CO), and other necessary documents to facilitate the customer’s customs clearance process.