Quality Control

Outstanding quality will be essential and supportive for excellent sales performance. As a valued supplier, we must all think of the end customer who will buy our garments. Our compliance to deliver first-class quality products is essential for a long-term trusting partnership and benefits mutual business interests between customer and us. For that reason, we’re continuing efforts to improve quality and increase value we provide to our customers.

Right First Time

Quality Assurance

Right first time,RFT, everyone is always doing the job correctly and efficiently at “right first time” every time, throughout development and production stages. so there are no delays or additional costs in the production processes. RFT philosophy is that preventing defects is more cost effective & efficiency than inspecting for defects.

Quality Assurance based systems focused on prevention of defects from product development, production, and distribution of products into retail. For this reason, we’re transforming to QA from QC

Quality Assurance and RFT complement & support each other and will improve both the product quality and the process efficiency, resulting in costs deduction significantly while best supports customer satisfaction.

Color Standard

Consumers react to how a product looks. For woven or knitted garments, color of fabrics and visible trims is one of the most important parameters. For that reason our company is paying very close attention to the color of the garments. Color samples (lab dip, strike-off, hand loom sample) must pass a visual assessment against the revelant color standard. Hence, we strictly follow the color assessment flow

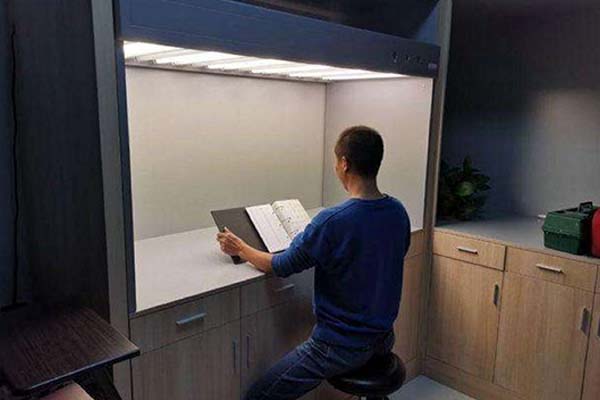

- An approved lighting cabinet located in a dark room or in a curtained off area

- Cabinets need to be fitted with D65 Artificial Daylight, TL84 General Store Light (F11) and UV Ultraviolet, using firstly D65 and then secondly TL84.

- Only trained colorist who have passed the Farnsworth - Munsell Color Discrimination Test (score 24 or less) can approve the color standard

- The visual evaluation is the primary source for color assessment. Digital assessment (Datacolor SF600) as secondary source is used to appoint the direction for color correction

Fabric & Trims Inspection

4 point inspection system

We ensure rigorous fabric quality control through our state-of-the-art fabric inspection machines and a meticulous “4 point” inspection system. Our inspection reports provide detailed information on fabric dimensions, weight, color accuracy, shading consistency, texture, design patterns, construction, defects, and adherence to physical and color testing standards. We are committed to achieving excellence at every stage of the process, guaranteeing accurate and superior outcomes consistently.

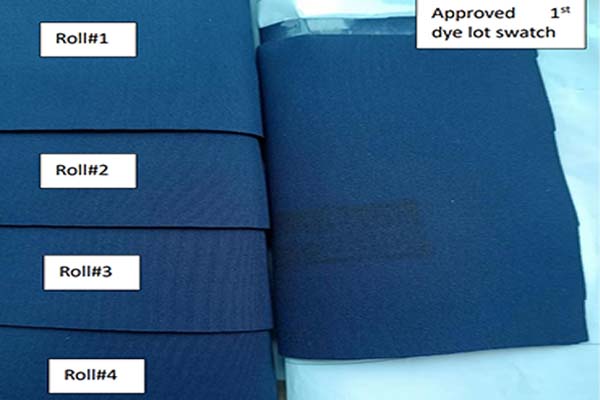

Colour continuity

Color is a very important part of the approval process. Incorrect color approval leads to problems such as garments within a range may not fit in with the rest of the range, shading within a garment, shading from garment to garment. To aviod this, our fabric QC using the grey scale and review color continuity card to ensure shade consistency from roll to roll, and batch to batch.

Fabric & Garment Test

To be competitive globally, we adopts international test methods widely used by top retailers and wholesale companies. Each season, we update our testing requirements of fabrics and materials to be used in the manufacture of private label, wholesale and licensed branded products

Physical performance testing

- Weight

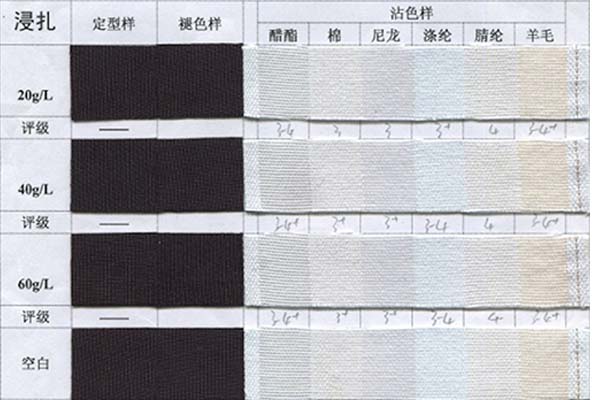

- Color fastness

- Lenear density of yarn

- Water repellence

- Dimensional stability

- Abrasion resistance

- Bonding strength of seam seal tape (Water Proofing)

- Color Migration for contrast placement print

- Hydrostatic

- Down Composition

- Tear strength

- Moisture vapor permeability

Chemical performance testing

We have signed the reach letter about restrict the use of certain chemicals in our apparel products, All our products can meet the latest version of REACH test. latest reach test, just to name a few, free of AZO,PFOA PFOS, DMF, Cadmium, Chromoum VI, lead, mercury, nickel release etc.

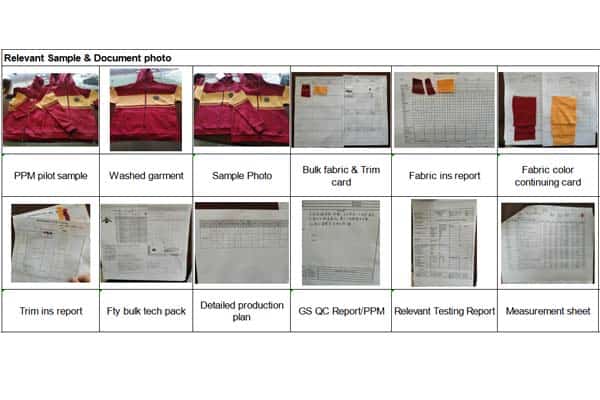

Pre-production Meeting

We hold Pre-production meeting to discuss in depth to ensure all relevant parties fully understand the quality, technical and production requirements prior to starting production

- Review PPS comments

- Review quality & measurement of pilot run sample, make comments, and put an action plan in place if necessary

- Review incoming inspection reports for bulk fabrics and trims

- Review color continuity card to ensure shade consistency from roll to roll, and batch to batch.

- Review appearance of washed garment sample and test results

- Review sewing needle requirements

- Review risk assessment results

- Any other concerns for product quality

In-line Inspection

In-line Inspection is performed during the assembly and finishing process of production to verify whether finished garments have met all requirements per technical specification details and quality callouts at PPM during production

The Inline Inspection reviews the entire manufacturing processes of garment production (cutting, sewing, auxiliary processes, measurements, workmanship, trimming, and finishing etc). All styles in each colorway must be inspected during In-Line inspection.

Final Inspection

The Final Inspection process determines whether the garment production corresponds to the approved standards of quality, measurements, and packing requirements.

Metal detecting must be implemented to guarantee metal free on garment – full product scanning once packed in polybag, before packing products in master carton.

- We’ll send your weekly report about the production status

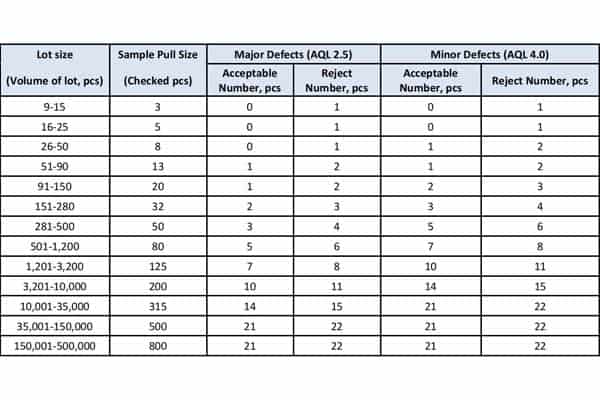

- All Quality inspections of garment and accessory will be performed according to AQL Standard and DCL (Defect Classification List)

- Defective products found during inspection must be repaired or sorted out before re-inspection and shipment

- We will issue a Final inspection report with passing or failing results upon completing inspections

- We defenitly not ship products before passing Final Inspection. All exceptions must get approval from Customer