Why Choose Us

Faster Sample Leading Time

Our team is equipped to deliver standard jacket samples in 5-7 day and finish a complicated one in 7-10 days, outpacing our competitors' speed.

Bring Ideas Into Physical Prototypes

All you need to do is to send us your design or marker sample. Our sampling team will find a smarter way to turn complex designs into high-quality, functional samples upon your requirements.

Attract Your Customers

A high-quality prototype jacket is an effective marketing tool, capturing the interest of prospective your customers or investors. That's why we invest substantial resources into creating impeccable designs and samples

Unsurpassed Quality

Our sample masters, pattern experts and sampling workers are comprised of seasoned professionals with over two decades of experience. Their cohesive collaboration ensures exceptional sample quality and accuracy of fit.

Professional Solutions

Our sample specialist not only ensures the quality and craftsmanship of samples, but also delivers outstanding solutions in terms of jacket construction, material selection, design, fit, and more. This can greatly reduce your costs

Trendy Designs

Our designers create approximately 300 unique designs each season. They stay abreast of current fashion trends and incorporate them into the jacket's stylish look.

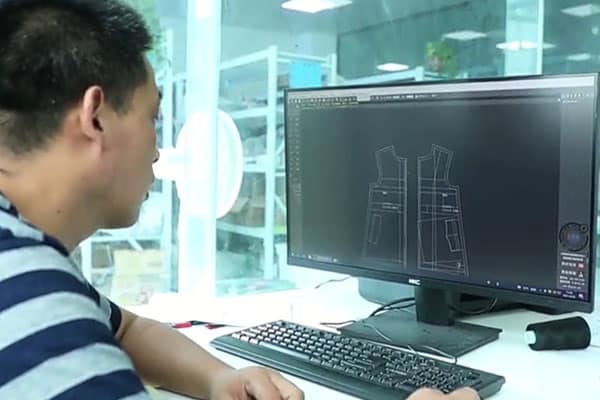

CAD PATTERNING

Analysising

Upon receiving the tech pack, sketches, design, or sample jacket, our sample master and pattern experts will collaborate to analyze the jacket’s construction details, material requirements, and craftsmanship before proceeding with pattern creation. Our textile specialists partner with customers to ensure clear communication of ideas and concepts, which is crucial for enhancing design and speeding up delivery

CAD systems

Our pattern expert utilizes CAD systems to create digital patterns and print them onto marker paper using a plotter. This requires exceptional expertise to transform a 2D fabric into a functional and well-fitting 3D garment. The use of CAD software ensures increased accuracy in pattern making, leading to a better fit.

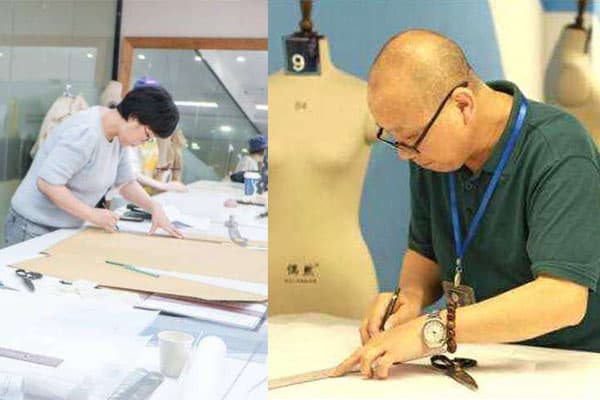

Sample Making

Sample Analyzing

Our sample master’s contribution is vital to the success of the sample making process and the final product. they also use traditional pattern making techniques to create paper patterns ensure precision and a perfect shape that the designer intended.

Sample Making

Our skilled sample makers with 20 years of extensive experience can create a well-shaped jacket from paper patterns. They pay attention to every detail, including stitching methods, construction instructions, buttons, zippers, snaps, toggle systems, and more. We take pride in our meticulous workmanship and dedicated approach.

FITTING & AMENDING

Fitting

After creating a sample garment, we conduct a comprehensive garment fit checking meeting to compliance with your specifications. In this meeting, we carefully assess the fit of the garment on both a dummy and a live model, and make necessary adjustments to the 3D cutting pattern using our sample master’s expertise. This meticulous process ensures that the final product meets your exacting standards and requirements.

Amending

The initial sample of the custom jacket is now available for your evaluation of its appearance and quality. Please examine it to see if it meets your requirements. If the sample is up to your standards, it can proceed to large-scale production. If any adjustments are required, we will create mock-ups or a new sample incorporating your suggestions. We will keep you informed throughout the entire process and will not take any steps without your consent.